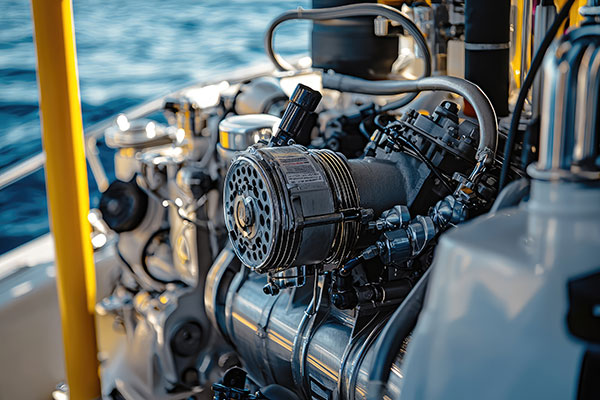

Marine engine corrosion is one of the most common threats to engine integrity, performance, and operational lifespan. It occurs when metal surfaces deteriorate due to chemical reactions with their surrounding environment. In the marine sector, these reactions accelerate significantly because vessels operate in conditions where salty air, humidity, fluctuating temperatures, and fuel characteristics create the perfect combination for corrosion to develop.

Understanding the causes and behavior of marine engine corrosion is essential for vessel owners and operators who want to protect their engines, maintain efficiency, and reduce long-term maintenance costs.

Main types of marine engine corrosion

Marine engines are exposed to various corrosion mechanisms that affect different materials and components. The most common include the following:

Galvanic corrosion

Galvanic corrosion occurs when two dissimilar metals come into electrical contact in the presence of an electrolyte, common in seawater environments. Metals like aluminum, frequently used in modern engine blocks, housings, and external parts, are particularly vulnerable. Aluminum engine corrosion tends to appear rapidly when paired with more noble metals, resulting in material loss and weakening of the affected components.

Cold corrosion in main engines

Cold corrosion is typically a concern in large marine engines operating on fuels with higher sulfur content. When exhaust temperatures drop too low, sulfur compounds combine with moisture to form sulfuric acid, which then condenses on cylinder liners and piston surfaces. Over time, this acid leads to severe liner wear, scuffing, and reduced engine efficiency. Low-load operation, slow steaming, and poor fuel quality can all intensify cold corrosion.

Pitting, crevice, and surface corrosion

These forms of corrosion differ in appearance and impact:

- Pitting corrosion creates small, deep holes that penetrate metal surfaces and compromise structural integrity.

- Crevice corrosion occurs in narrow gaps such as gasket areas, joints, and under deposits where oxygen levels are low. Surface (uniform) corrosion appears as an even layer of deterioration across exposed areas.

Internal engine components (such as liners, pistons, valves, and fuel pump elements) are vulnerable to chemical reactions and acidic residues. External areas like engine blocks, cooling systems, mounts, and housings tend to suffer from moisture-driven corrosion caused by seawater exposure and condensation.

Common signs of marine engine corrosion and where it usually appears

Detecting corrosion early helps prevent costly damage. Key warning signs include:

Engine cylinder corrosion

Loss of compression, reduced power, smoke, and occasional misfires.

Corrosion on engine block

Discoloration, flaking paint, and localized weakness around mounting points or cooling passages.

Other areas commonly affected include exhaust manifolds, turbocharger housings, seawater pumps, fasteners, brackets, and heat exchangers. Any visible rust, residue buildup, or leaking around gaskets may indicate advanced corrosion.

Cleaning and removing marine engine corrosion

Corrosion removal depends on severity and component material. Light corrosion on external areas can typically be cleaned with approved marine-grade cleaners, mild abrasives, or neutralizing agents. When cleaning aluminum, operators must avoid overly aggressive methods that may scratch or weaken the metal.

Internal corrosion (especially in cylinders or fuel systems) often requires partial disassembly for proper inspection. Severely deteriorated components such as liners, pumps, or exhaust parts may require full replacement to restore safe operation.

How to prevent marine engine corrosion with the right lubricants and fuel

Preventive maintenance is the most effective defense against marine engine corrosion. Key considerations include:

- Lubrication. Oils with adequate TBN (Total Base Number) help neutralize acidic byproducts, reducing the risk of cold corrosion and liner wear.

- Anti-corrosion additives. Quality lubricants form protective films that shield metal surfaces from moisture and chemical attack.

- Fuel quality. Using ULSD (Ultra-Low Sulfur Diesel) or MGO (Marine Gas Oil) minimizes sulfuric acid formation, especially in engines operating at lower loads.

- Regular oil changes. Following OEM recommendations ensures that oil maintains its protective properties and reduces contaminants.

- Routine inspections. Monitoring temperature profiles, deposits, filter conditions, and combustion performance helps detect early corrosion trends.

Royal Petroleum: fuel and lubricant solutions to protect your engines

Royal Petroleum supports the marine industry with reliable, high-performance lubricants and fuels, alongside technical expertise designed to safeguard engine systems against corrosion and ensure smooth, efficient operation. Our marine products portfolio includes:

- Premium lubricants for all engine types, formulated to maintain cleanliness and reduce corrosive wear.

- Clean marine fuels, such as ULSD, which minimize sulfur residues and promote efficient, low-corrosion operation.

With Royal Petroleum, marine operations benefit from consistent product quality and technical support that help keep engines protected and running efficiently.

Protect your vessel from corrosion: get expert support now

Marine engine corrosion is entirely manageable with the right knowledge, preventive practices, and professional support. By selecting high-quality fuels, the correct lubricants, and maintaining a consistent maintenance schedule, vessel operators can extend engine life and ensure reliable performance at sea.

For expert guidance and product recommendations, visit royalpetroleumpr.net. To explore Royal Petroleum’s full catalog, click here.

Work Cited:

- American Society for Testing and Materials. ASTM G15: Standard Terminology Relating to Corrosion and Corrosion Testing. ASTM International, 2023.

- British Standards Institution. BS EN ISO 8044: Corrosion of Metals and Alloys – Basic Terms and Definitions. BSI, 2020.

- International Maritime Organization. Guidelines for the Reduction of Sulphur Oxide Emissions from Marine Engines. IMO, 2021.

- S. Department of Energy. Clean Diesel and Low-Sulfur Fuels Overview. Energy.gov, 2023.